Project Goal

The Glass-TAOO project aimed at achieving innovations with industrial partners located along the entire process chain of glass production – raw material producers, glass manufacturers, equipment manufacturers, semi-finished product manufacturers, end-users of glass products – through technology transfer in the cross-cutting topics of Efficient Production Technologies – Green Factory and Clean Technology. The project objectives were geared to both increased efficiency in production and resource efficiency.

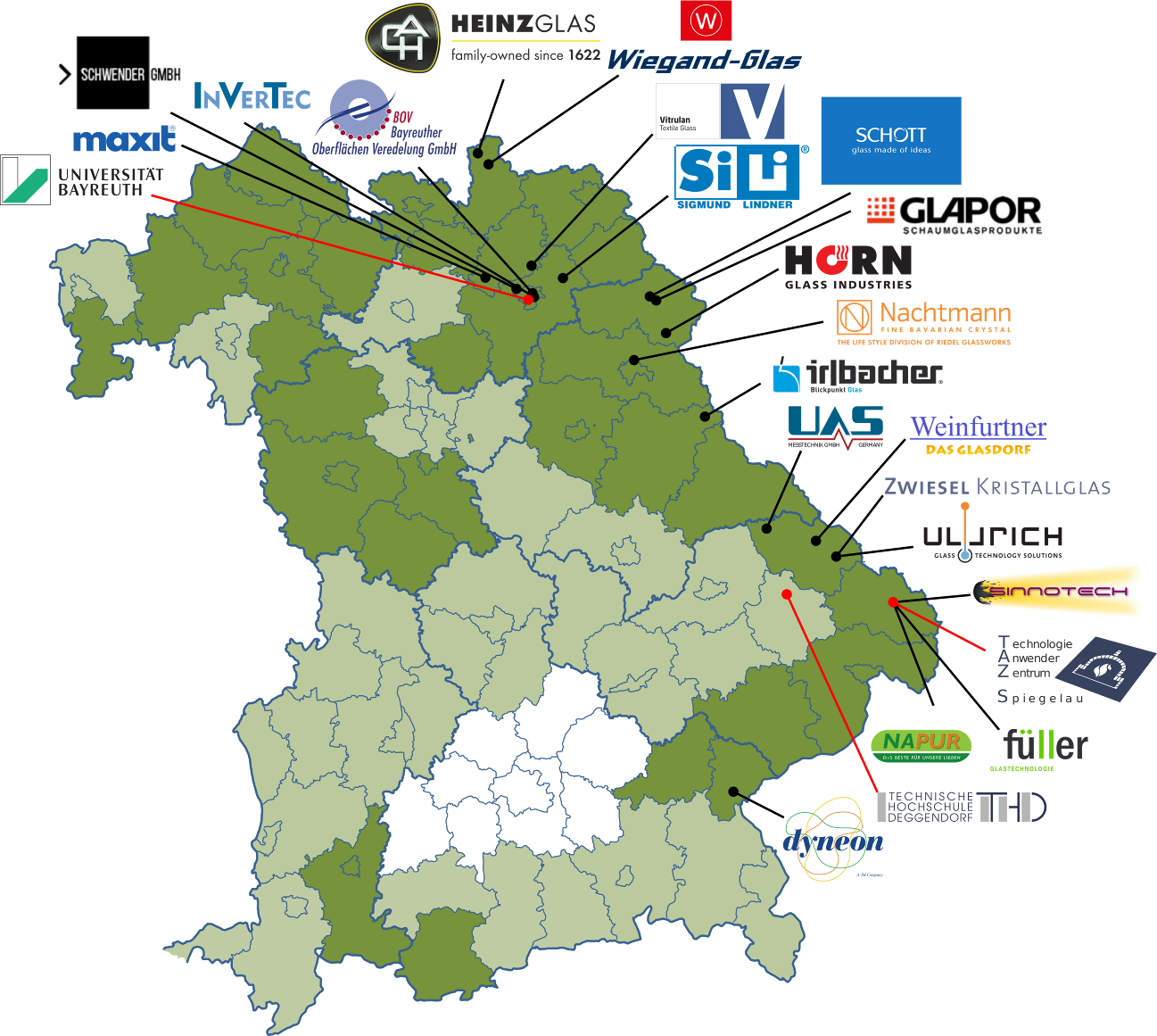

The joint innovation initiative enabled a long-term and sustainable technology transfer between the regional glass industry in Upper Franconia and Eastern Bavaria and the University of Bayreuth as well as the Technology Application Center (Technologie Anwender Zentrum, TAZ) in Spiegelau. Both the University of Bayreuth and the TAZ Spiegelau (the supporting university is the Technical University of Deggendorf, THD) have for many years had project collaborations with the glass industry that deal with application-oriented product and process development, especially for glass-based products for the construction, energy and packaging sectors. With the project Glass-TAOO, technology development and technology transfer between TAZ/THD in Eastern Bavaria and in Upper Franconia at the University of Bayreuth was consolidated beyond the funding period.

Main topics

Efficient Production Technologies

- Flexibilization of glass production through the use of combined electrothermal heating processes and mechatronic processing machines

- Down-scaling of glass melting units to make production more flexible

- Quality assurance through novel methods of in-situ process monitoring and control

- Automated production and new process windows for the manufacture of functionalized glass additives for the construction, transportation and energy industries

Clean Technology

- Closing of the material cycle through advanced up-cycling of end-of-life glass and through exploitation of previously unused residual materials and minerals

- Energy storage, especially decentralized and grid-flexible „demand-site“ energy management to significantly increase the energy efficiency of glass production

Cooperation structure

The Glass-TAOO Bavaria Technology Alliance was open to all interested SMEs as part of its project activities. The following map provides an overview of the Glass-TAOO project partners that have grown over time:

Project Profile

|

Duration: 01.03.2016 - 30.09.2020 Funding: European Regional Development Fund (ERDF) |

|

|

|

Contact: Prof. Dr.-Ing. Thorsten Gerdes, Dr.-Ing. Andreas Rosin, Dr.-Ing. Daniel Leykam |

||