Analytics

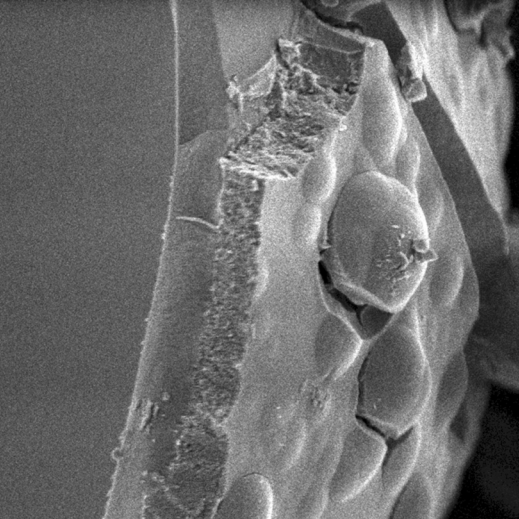

From a thermodynamic point of view, glass is a frozen, supercooled melt. The surface of just solidified glass can be as smooth as that of a solidified liquid. The roughness of flat glass is as low as 0.2 nm. Even such small irregularities, however, can be made visible with special microscopes. The structure of surfaces is generally of great importance, as these define the interfaces between the glass and the environment or coating.

The analysis of surfaces is also a focal point for Keylab Glass Technology. The properties of juvenile glass surfaces and their changes due to shaping, coating or storage, for example, are investigated both on model glasses and on technical products such as beverage bottles, glass tubes or crystal glasses.

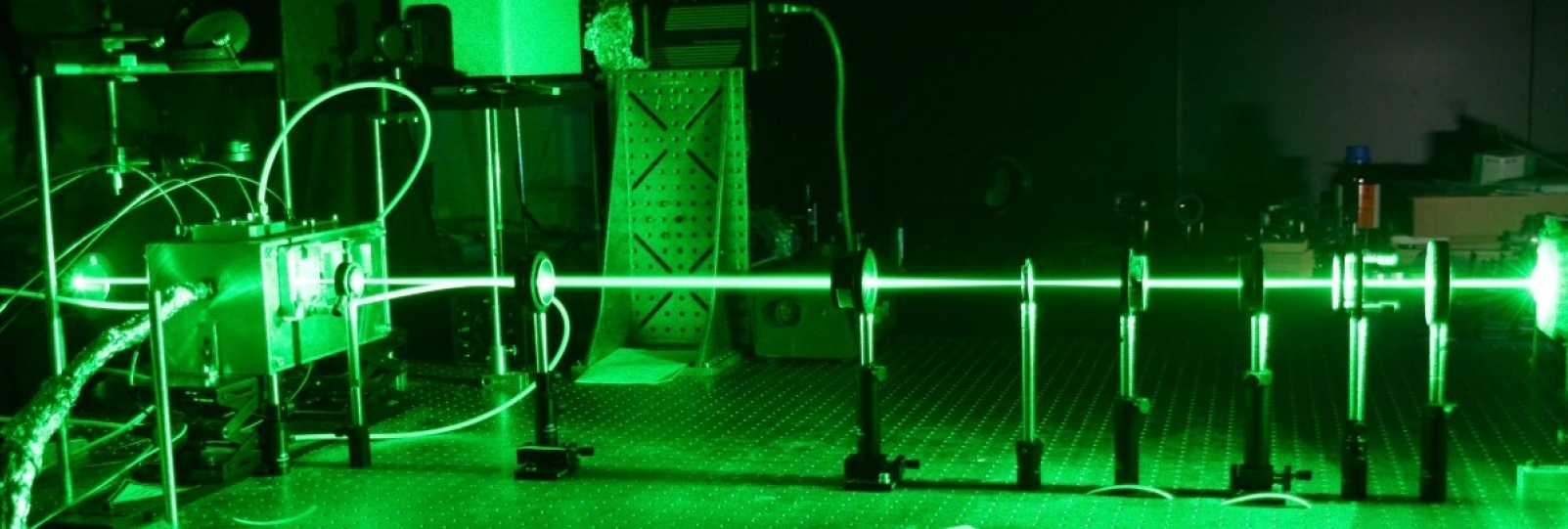

The special features of glass, an electrically non-conductive material (at low temperatures), require special analysis methods, sample preparation and measuring equipment. The measuring methods used include conventional light and electron microscopy, ellipsometry, reflectometry, FTIR, plasma and Raman spectroscopy, X-ray diffraction and profilometry, field emission scanning electron microscopy (FE-REM) with energy dispersive element analysis (EDX), atomic force microscopy (AFM), and chemical depth profile analysis with photoelectron spectroscopy (XPS), Auger electron microscopy, and secondary ion mass spectrometry (SIMS), among others.

A wide range of materials science and physical investigation methods such as dilatometers, tribometers, micro-hardness measurement, dynamic mechanical and thermo-mechanical analysis, thermogravimetry, gas and mercury porosimetry, and nuclear magnetic resonance measurement are available for determining volume properties.

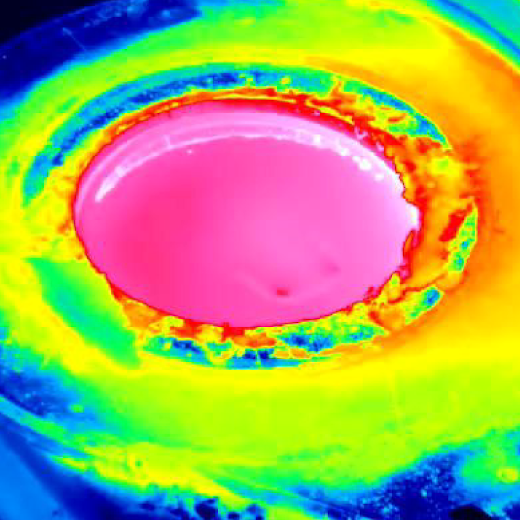

Manufacturing and processing processes are examined with thermography and high-speed cameras, among others.