Glass-based Insulation Materials

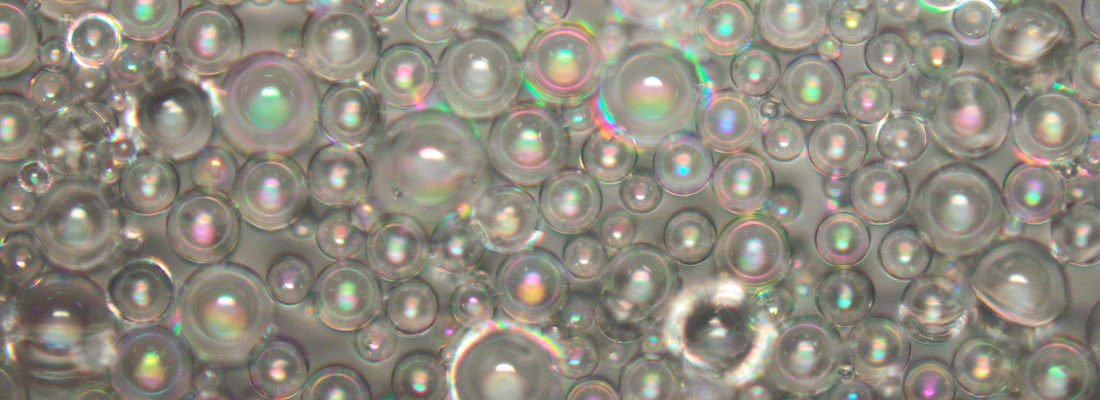

Micro hollow glass spheres are free-flowing powders of spherical glass particles. The unique combination of spherical shape with wall thicknesses in the range of 0.3 to 2 µm at diameters of 10 to 200 µm, extremely low density, relatively high strength and good thermal and acoustic insulation have made Micro hollow glass spheres an important filler material, e.g. for polymer materials, since the 1970s.

The Keylab Glass Technology is investigating the combination of these unique properties of Micro hollow glass spheres with classic building material systems based on plaster and mortar. The research work carried out will, for example, result in Micro hollow glass spheres-based insulation systems that have similar insulation properties to those of the expanded polystyrene (EPS)-based systems preferred today. In contrast to EPS insulation materials, however, the insulation systems with Micro hollow glass spheres as a pure mineral filler are much easier to recycle. The risk of fire is also significantly reduced.

In addition to studies on the continuous improvement of the incorporation of Micro hollow glass spheres into plasters, the use of these novel insulation systems is currently being investigated by the Keylab Glastechnologie on real buildings at various locations in Bavaria.

Beyond the material systems plaster and coatings, the focus of the Keylab Glass Technology is on incorporating Micro hollow glass spheres as a filler into other materials and products, e.g. polymers and paints, in order to specifically modify and improve their properties.

In order to ensure optimal bonding to different matrix materials, various coatings of the Micro hollow glass spheres are tested at the Keylab Glass Technology. In addition, it is possible to modify the Micro hollow glass spheres composites and the Micro hollow glass spheres itself by means of such coatings. This includes, for example, their reflective behavior, strength and thermal conductivity.

These are tested in the laboratory scale at the Keylab Glass Technology and then transferred to the demonstrator scale together with industrial partners.

In addition to the properties of Micro hollow glass spheres composites and components, the manufacturing process of Micro hollow glass spheres is also being continuously developed in parallel in order to further reduce the gray energy of the new insulation and materials and increase the overall energy efficiency.