Glass Processing

Many manufacturing processes have been established in the glass industry for decades. However, the challenges of the international market constantly demand the search for technical and economic improvements.

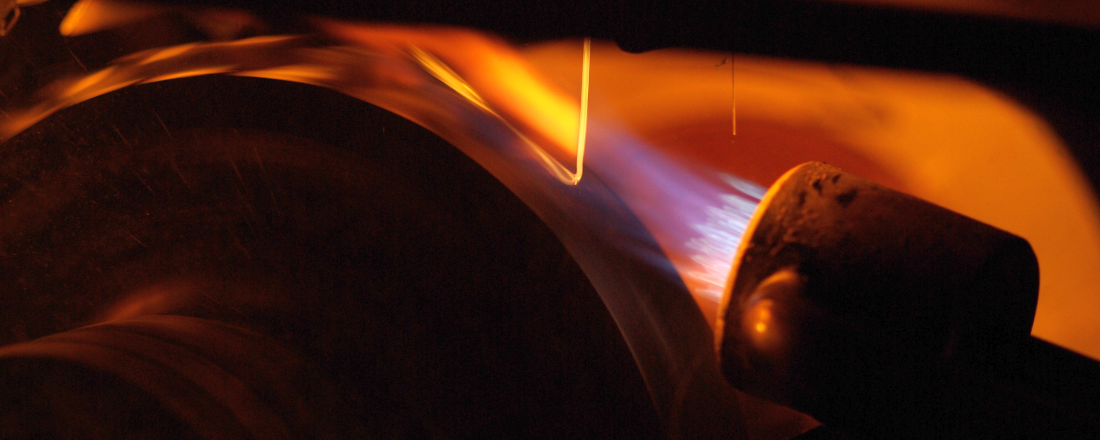

The Keylab Glass Technology contributes to the testing of ideas for novel concepts and process variants. Various facilities are available for this purpose. Of particular interest is a glass melting unit with which small batches of 100 kg of glass can be melted and fed to various shaping methods. The glass can be pressed, blown or centrifuged. Compared to glass melting tanks in industrial production, the operating parameters of this pilot plant can be changed much more flexibly. The melt temperature, which is important for glass processing, can be varied and changed in a relatively short time. The open design of the plant allows direct insight into the furnace and in-situ measurements on the hot glass melt.

For example, the effects of the shear cut on the glass drop and the subsequent shaping (e.g. gob or flake production) are investigated. For this purpose, the entire process from cutting to falling into the mold is followed with a high-speed and/or thermal imaging camera and possibilities for optimization are derived.

The heat transfer between glass and mold is also investigated. For example, in one processing operation, the molten glass was formed into thin lamellae by a rapidly rotating body. In particular, the flow is highly coupled to the viscosity of the molten glass. Systematic investigations using mathematical and physical models have made it possible to improve the flow and heat transfer between mold and glass in order to extend the process limits.

In addition to the production of thin glass lamellae, processes for the manufacture of hollow and micro hollow glass spheres are also being systematically investigated. Sphericity, homogeneity and size of the spheres produced are closely linked to the addition of blowing agents and the processing of the ground glass powder.

The investigation and continuous expansion of glass processing technologies are an important step on the way to new semi-finished glass products, molding materials and material concepts.