Prozess Simulation

Numerical simulation with modern computers is an important tool for saving development time and avoiding costly mistakes. In the first step, the relevant processes are identified and translated into physical-chemical models, which are then converted into mathematical equations and numerically solved using special computational methods.

The Keylab Glastechnologie carries out simulation calculations that can be used to determine even hidden properties or difficult-to-measure quantities of glass processes and glass products. The results thus provide valuable information for improving manufacturing and processing procedures.

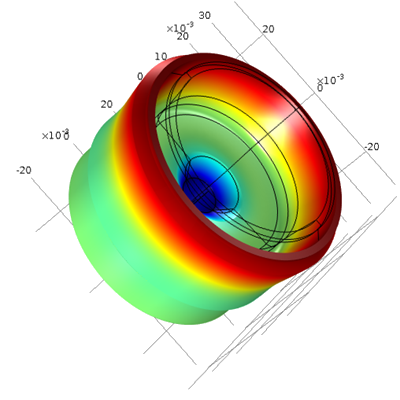

For example, residual stresses in thermally treated glass products can be calculated and related to the cooling process. This is particularly useful for products with complex shapes. Such simulations are an important basis for the optimization of the cooling process and the reduction of internal stresses as well as for the specific adjustment of glass properties.

Simulation can be used to describe thermo-fluid dynamic processes during glass melting. Through model and parameter variation, a verified model can be used to optimize a glass melting tank or improve the residence time behavior. In any case, the simulation allows insights into areas that are otherwise difficult to see.

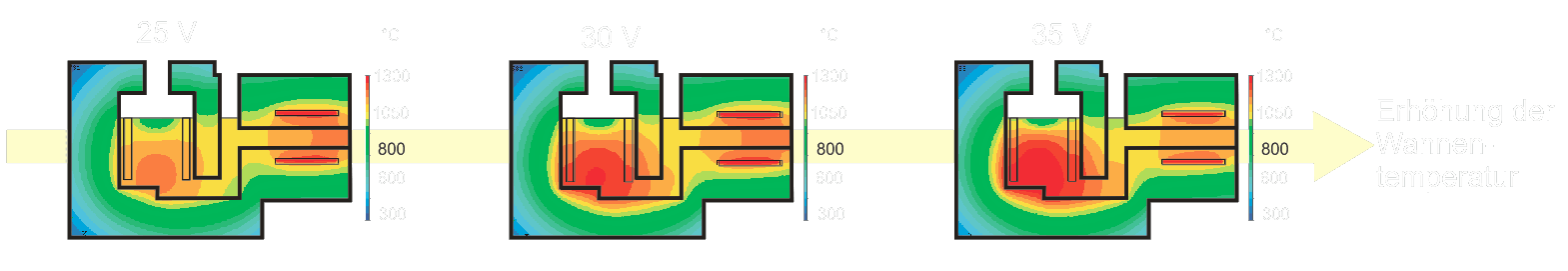

The simulation can also be used to represent the glass processing that follows the melt. For example, the thermal deflection of glass sheets could be successfully mapped or the heat supply in processing machines could be optimized.

Despite its interesting possibilities, computer simulation cannot replace experiments. The calculations include material properties as parameters, which must be measured. In addition, models must be validated and improved by comparing simulation and measurement results. Keylab Glass Technology is developing and applying measurement methods specifically for glass, including optical emission spectroscopy and thermography. Both methods enable a non-contact analysis and characterization of the glass surface - not only for laboratory samples, but also during the manufacturing and processing process.