Post-fossile Melting Technologies

The need to meet climate targets requires not only a move away from fossil-fuel heated glass tanks in favor of all-electric heated tanks, but the development of completely new plant and operating concepts.

According to a recent study by the Federal Environment Agency, "Greenhouse Gas Neutral Germany in 2050," the 4.8 TWh final energy demand of the German glass industry is to be completely converted to renewable energies by 2050, i.e., energy-related greenhouse gas emissions are to be reduced to 0 t CO2 eq/a.

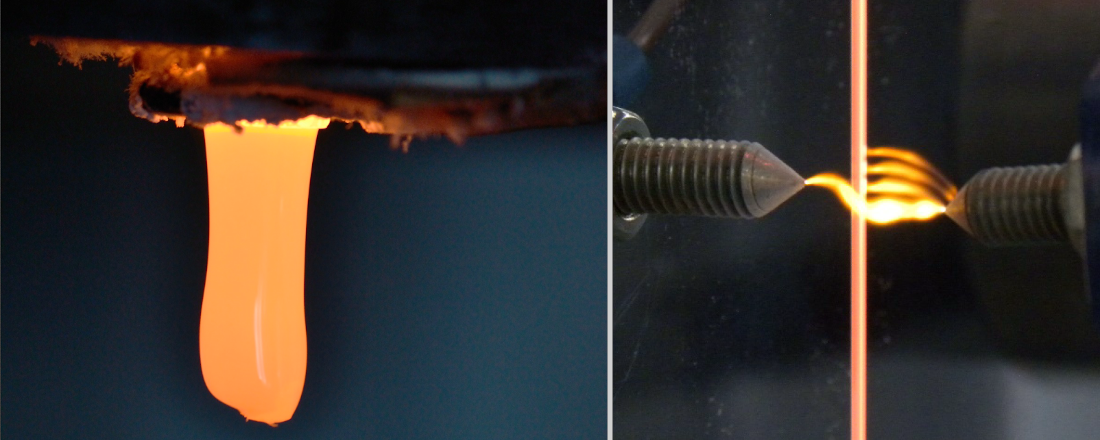

With the progressive move away from fossil energy sources, an expansion of the capacity of fully electrically operated glass furnaces is forecast. In order to make the operation of electric furnaces more flexible in terms of demand side management, a new generation of electric furnaces is being designed and tested at the Keylab Glastechnologie that can tolerate fluctuating energy input as well as variable temperatures and levels of humidity.

The Keylab Glastechnologie has over ten years of experience in the operation and design of fully electric small melting units. The focus of research and development has been on optimizing the discontinuous operation of the melting unit so that production can be resumed quickly after an idle phase and a safe, energy-saving standby operation is possible for production interruptions. In order to be able to produce glass with consistent quality, numerous optimizations to the glass tank and the plant peripherals were successfully implemented together with the plant engineering partner.

The glass melting unit of the Keylab Glastechnologie has also been an important component in the materials science training of Bayreuth students in the field of glass production and processing for many years.